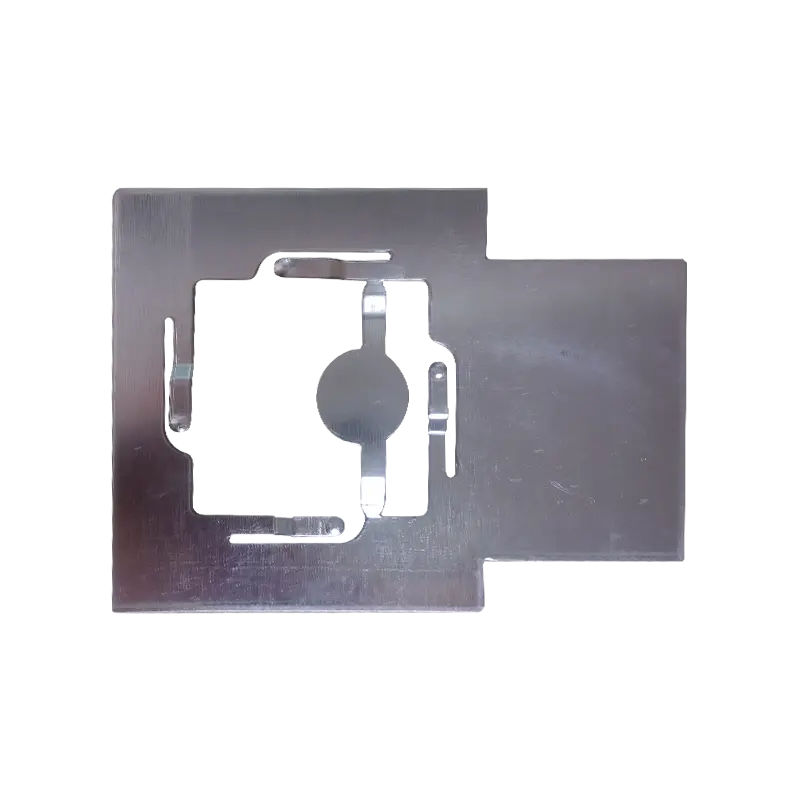

In today's era of increasingly stringent requirements for precision manufacturing, every tiny detail determines the success or failure of a product. Especially in high-tech fields such as electronics, communications, and medical devices, the requirements for the accuracy and flatness of parts are almost harsh. AD BOX Shield, as an outstanding product that combines high technology and exquisite craftsmanship, how does it achieve 0.1mm extreme flatness on thin materials of 0.1~0.2mm such as stainless steel, SPTE (tinned thin steel plate), and KU360S? Is high-precision continuous die stamping and fully automated testing really its whole secret?

Let's take a closer look at the materials used by AD BOX Shield. Stainless steel has become the first choice in many precision manufacturing fields with its excellent corrosion resistance and strength. Materials such as SPTE and KU360S, with their good conductivity and processing performance, occupy an important position in the manufacture of electronic devices. Although these materials have excellent performance, it is undoubtedly a huge challenge to achieve a flatness of 0.1 mm at such a thin thickness.

Faced with this challenge, the manufacturing team of AD BOX Shield chose high-precision continuous die stamping technology. This technology is not a simple stamping process, but requires precise mold design, strict process control and advanced production equipment. In the mold design stage, engineers need to accurately calculate the shape and size of the mold and the pressure distribution during the stamping process according to the characteristics of the material and the required flatness requirements. In terms of process control, every parameter such as temperature, speed, and pressure needs to be strictly controlled, and a slight deviation may lead to a decrease in flatness.

And advanced production equipment is the basis for all this. High-precision stamping machines can complete complex stamping processes in a very short time while maintaining extremely high stability and repeatability. This not only greatly improves production efficiency, but also ensures that every AD BOX Shield product can meet consistent flatness requirements.

High-precision continuous die stamping is only the first step to achieve 0.1 mm flatness. After the stamping is completed, fully automated testing is required to ensure the quality of the product. Traditional inspection methods often rely on manual operation, which is not only inefficient but also easily affected by human factors. AD BOX Shield uses advanced automated inspection equipment, which can accurately measure and analyze a large number of products in a short time through high-precision sensors and image processing technology. Once a defective product is found, the system will immediately sound an alarm and automatically remove it from the production line.

This fully automated inspection method not only greatly improves inspection efficiency and accuracy, but also reduces the impact of human factors on product quality. More importantly, it enables AD BOX Shield to detect and solve problems in a timely manner during the production process, thereby ensuring that every product can meet the highest standards required by customers.