1. Limitations of traditional wires

Traditional wires are usually made of copper or aluminum. Although they have good electrical conductivity, their cross-sectional area is relatively small when facing large-scale, long-distance power transmission, which limits the effective passage of current. This limitation will not only cause significant losses during the power transmission process, but also cause the system to heat up due to the resistive heating effect, which not only increases energy consumption, but also accelerates the aging of the wires and reduces the overall reliability and safety of the system. In addition, frequent system heating may cause fires and other safety hazards, posing a threat to people's lives and property.

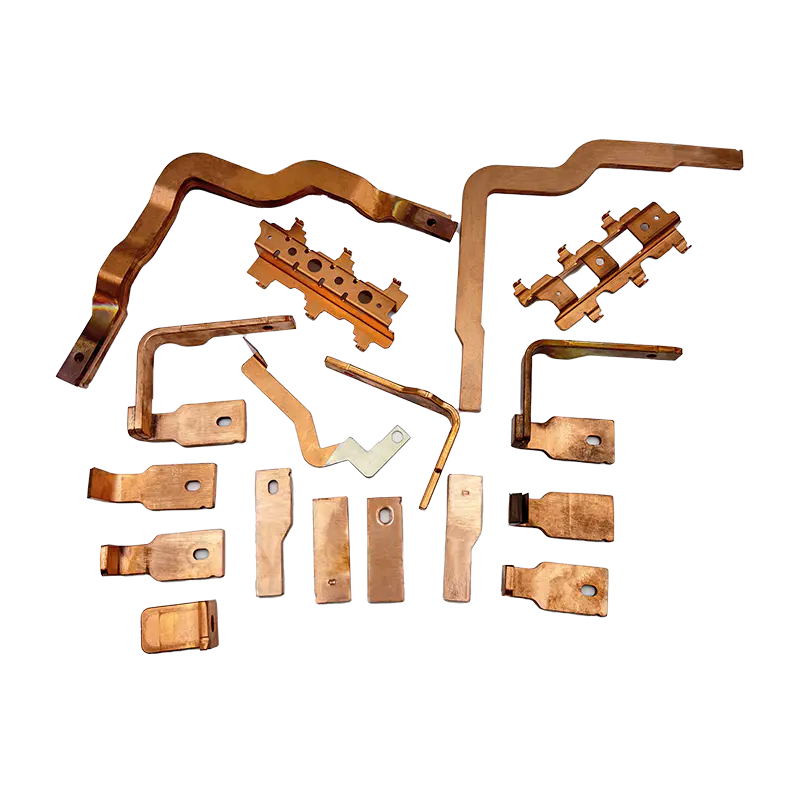

2. Large-section design of copper busbar

Compared with traditional wires, the biggest feature of copper busbars is their larger cross-sectional area. This design not only improves the conductivity of the material, but also provides a wider flow path for current on a physical level, thereby significantly reducing resistance. According to Ohm's law, resistance is inversely proportional to the cross-sectional area of ??the conductor. Therefore, the large-section design of the copper busbar can effectively reduce the resistance when current passes through, thereby reducing the proportion of electrical energy converted into heat energy, that is, reducing current loss.

3. Reduction of current loss and improvement of energy efficiency

Reduced current losses mean more power can be efficiently transmitted to the destination, rather than being wasted during transmission. This not only improves energy efficiency, but also reduces the system burden caused by heat generation and extends the service life of power equipment and cables. In large power facilities such as substations, data centers, large factories, etc., the application of copper busbars is particularly important. These places often need to handle large amounts of electrical energy, and the high losses of traditional wires will greatly affect operating costs and environmental benefits. Copper busbars can effectively solve this problem and provide stable and efficient power support for these places.

4. Relief of system fever and enhancement of safety

In addition to improving energy efficiency, the large cross-section design of the copper busbar also helps alleviate system heating problems. The reduction in heat generation directly reduces the risk of fire caused by overheating and enhances the safety of the power system. In addition, lower heat generation also means less maintenance requirements, reducing downtime and repair costs due to equipment failure, and improving the overall stability and reliability of the system.

5. Environmental protection and sustainable development

While pursuing efficient energy utilization, environmental protection and sustainable development are also important issues that cannot be ignored in today's society. By reducing electrical energy losses, copper busbars indirectly reduce the consumption of fossil fuels, help reduce greenhouse gas emissions, and promote the transformation of green energy. At the same time, as a recyclable resource, the recycling of copper is also in line with the concept of circular economy, further promoting environmental protection and sustainable development.