1. Precise mold design and manufacturing: the cornerstone of high-quality parts

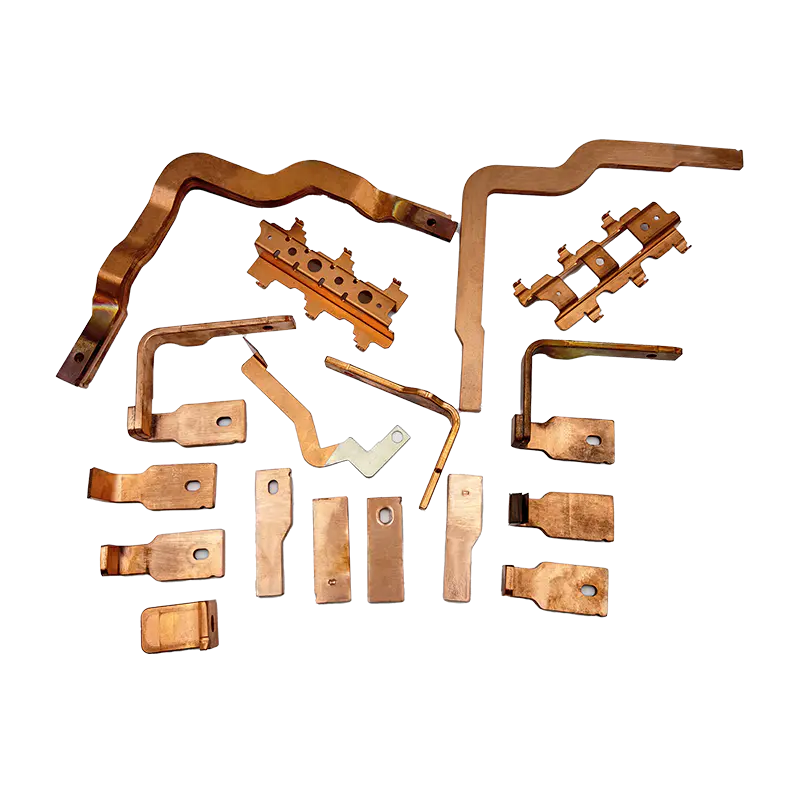

The precision and quality of Metal Stamping Service depends largely on the design and manufacturing of the mold. A high-quality mold can not only ensure the dimensional accuracy and shape consistency of the parts, but also improve production efficiency and reduce scrap rate.

Mold design: the combination of technology and art

Mold design is the core link of metal stamping service. Designers need to use advanced computer-aided design (CAD) software to accurately draw the three-dimensional model of the mold according to customer needs and part specifications. In the design process, designers must not only consider the size and shape of the parts, but also fully consider the fluidity of the material and the stress distribution during the stamping process to ensure the rationality and practicality of the mold.

Selection of mold material: balance between durability and precision

The selection of mold material has a vital impact on the durability and precision of the mold. High-quality mold materials, such as alloy steel, cemented carbide and high-speed steel, have high hardness, high wear resistance and high toughness, can withstand the huge pressure and friction during stamping, and maintain the precision and shape stability of the mold.

Mold manufacturing: precision technology and strict inspection

The mold manufacturing process includes mold processing, heat treatment, surface treatment and assembly. During the processing, high-precision CNC machine tools and EDM equipment are used to ensure the dimensional accuracy and shape consistency of the mold. Heat treatment can improve the hardness and wear resistance of the mold, while surface treatment can improve the surface quality and lubrication performance of the mold. During the assembly process, precision measuring and calibration equipment is used to ensure the assembly accuracy and stability of the mold.

2. Metal Stamping Service: Production process control to ensure component quality

In the production process of metal stamping services, a series of strict quality control measures are taken to ensure the accuracy and quality of components.

Raw material inspection: the source of quality

In metal stamping services, the quality of raw materials is the basis of component quality. When purchasing raw materials, suppliers need to be strictly screened and evaluated to ensure that their product quality is reliable. Strict inspection of purchased raw materials, including chemical composition analysis, physical property testing and surface quality inspection, ensure that the raw materials meet production requirements.

Stamping process optimization: precise control

The optimization of stamping process is the key to improving component accuracy and quality. During the stamping process, it is necessary to reasonably set parameters such as stamping speed, pressure and temperature according to the characteristics of the material and the shape of the parts. Use advanced stamping equipment and molds, such as servo stamping machines and multi-station stamping machines, to achieve precise control and automated production.

Online monitoring and feedback: real-time adjustment

In metal stamping services, sensors and monitoring systems are used to monitor key parameters and component quality in the stamping process in real time. Through data analysis, deviations and problems in the production process are discovered and corrected in a timely manner. Establish a feedback mechanism to adjust the stamping process and mold parameters according to the monitoring results to ensure the accuracy and quality of the parts.

Quality control and inspection: strict control

In the production process of metal stamping services, quality control and inspection are important links to ensure the quality of parts. During the production process, regular sampling inspections are carried out on parts to check whether their size, shape, surface quality and performance meet the design requirements. Establish a strict quality traceability system to record key parameters and data in the production process so as to trace the root cause of the problem and take corrective measures in a timely manner.

3. Continuous improvement and innovation: the future of metal stamping services

With the continuous development of the manufacturing industry and the changing needs of customers, metal stamping services need to be continuously improved and innovated to adapt to market changes and needs. By introducing advanced technology and equipment, optimizing production processes and mold design, improving production efficiency and component quality. Strengthen talent training and technical training to improve employees' skills and quality awareness. Actively carry out cooperation and communication with customers, understand customer needs and feedback, and provide customers with more high-quality, efficient and customized metal stamping services.