In the medical device industry, in order to meet the requirements of micron-level machining accuracy, many new materials have been introduced into manufacturing, which not only improve the precision of components, but also ensure biocompatibility and durability. For example, high-grade stainless steel, titanium alloys and special engineering plastics are widely used in medical device components because they can maintain dimensional stability during micron-level machining and meet strict precision requirements.

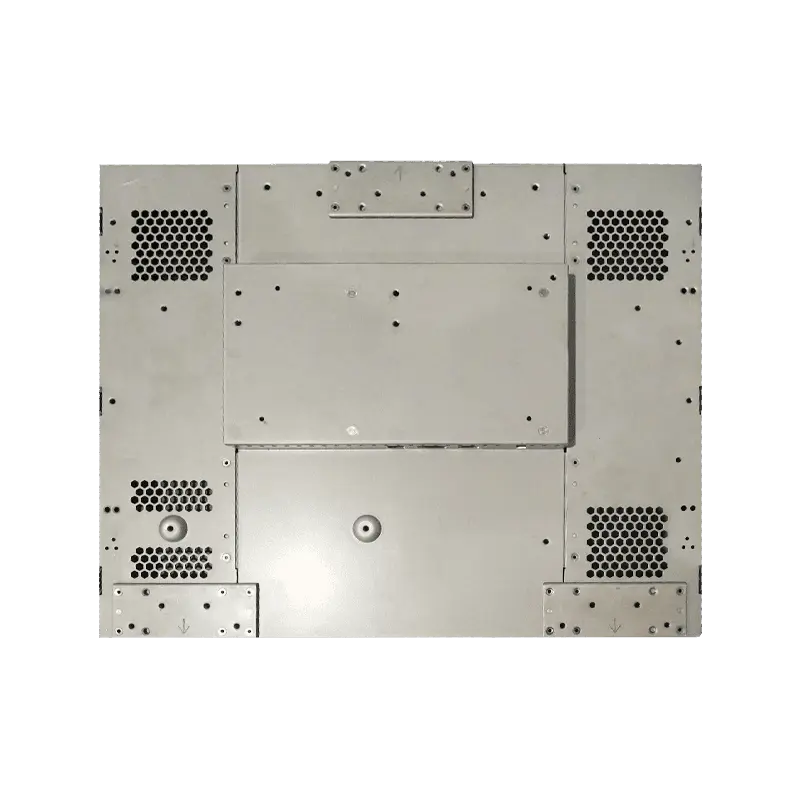

Suzhou Heaten Machinery Industry Co., Ltd has a leading advantage in the production of such high-precision medical device components. Heaten has rich experience in the application of materials such as stainless steel, aluminum, and copper, and is particularly good at using these materials for deep drawing and precision metal mold design. In the production process, the company uses high-precision stamping and mold manufacturing equipment, including 110T to 1000T stamping equipment and a variety of high-precision mold equipment, such as wire cutting machines, machining centers and precision grinders. These equipment can achieve micron-level machining accuracy, ensuring that medical components meet high precision and high performance requirements.

In order to ensure the accuracy and quality stability of the components, Heaten is also equipped with advanced testing equipment such as three-dimensional coordinate measuring machines, 2.5-dimensional measuring equipment, and salt spray testing machines. With certification standards such as IATF16949, ISO9001, and ISO14001, Heaten strictly controls every detail in the manufacturing process to ensure the accuracy and durability of each medical device component.

Through the application of materials such as stainless steel and titanium alloys, and the support of high-precision equipment, Suzhou Heaten has demonstrated its strong strength in producing medical device components that meet micron-level precision. This combination of innovative materials and precision machining has helped improve the accuracy and reliability of medical devices and brought high-quality solutions to the industry.